Research

Biomass conversion

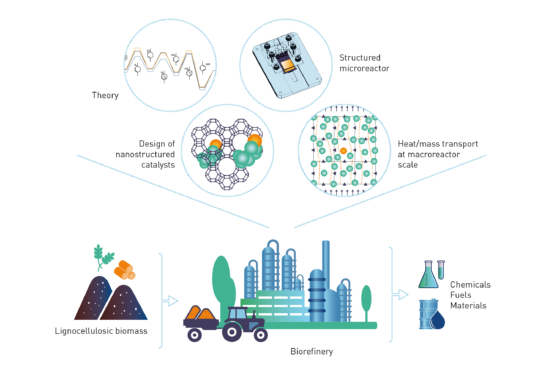

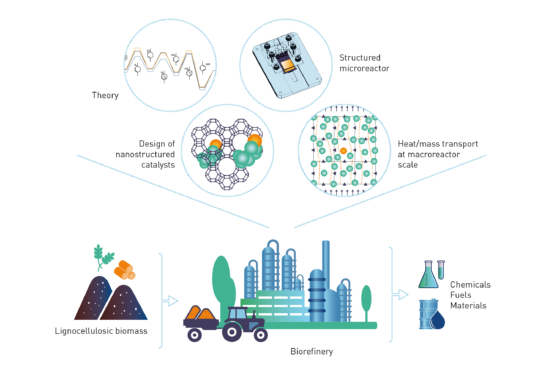

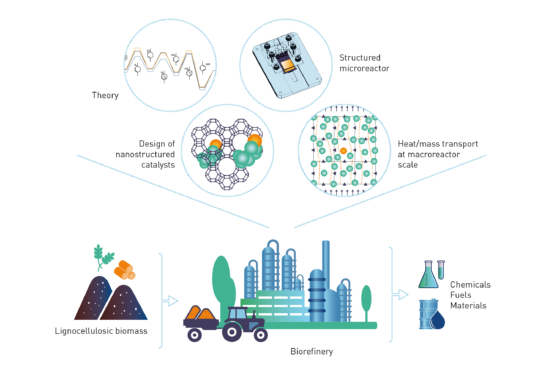

In the MCEC biomass cluster a consortium of researchers will investigate the conversion of biomass into useful products, such as base chemicals, synthesis gas and synthetic fuels. The entire knowledge chain is addressed by considering all relevant time and length scales. At the nano-scale an optimal design of the internal structure of the multifunctional catalyst is needed to achieve a high product selectivity and to counteract catalyst deactivation, which takes place due to the presence of water and/or coking. Catalyst design is aided by theoretical and multi-scale modeling studies. At the micro- and meso-scale one requires a proper understanding of the interplay between mass transfer and kinetics, which takes into account the external structure of the catalyst. Finally, at the reactor scale the interplay between flow phenomena, mass transfer and reaction is needed to make a priori predictions of the reactor performance. The research carried out in this cluster will lead to new recipes for catalyst and catalyst structure formulation, a quantitative descriptive model for mass transfer and kinetics for specific catalyst structures, and first-principle predictive tools for reactor performance prediction. These tools will help us to shift towards a biobased economy.