Polyalcohol reforming to synthesis gas as logistic fuel for mobile fuel cell applications

The current project aims at in depth understanding of coke formation mechanisms at the surface of heterogeneous catalysts under conditions of oxidative steam reforming of polyalcohols on microscopic and molecular level.

To reach these goals, theoretical modelling (DFT), ex-situ and in-situ characterization techniques will be applied, which will be assisted by extensive evaluation of the catalyst performance under practical operating conditions. The target is the development of catalyst formulations, which are long-term stable and do not show deactivation through coke deposition.

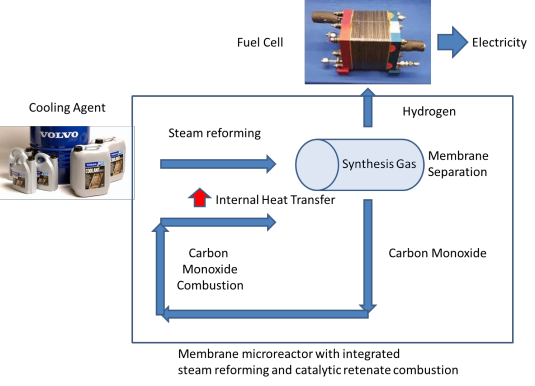

A reactor design for an integrated membrane microchannel reformer based upon plate heat-exchanger technology will be developed, which will comprise the reforming, hydrogen purification and off-gas (retentate) combustion in a single heat-integrated device. The design can serve as basis for a future product development in the field of fuel cell auxiliary power units for aviation and military applications based upon fuel cell technology.

Project leader: Prof. Gunther Kolb