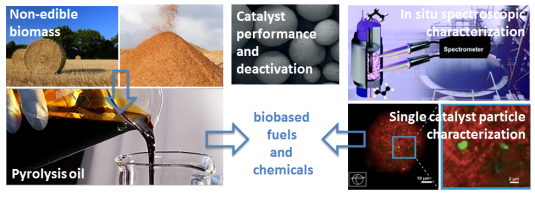

Bio-oil to chemicals and fuels: (in situ) catalyst deactivation studies at multiple length scales

Sustainably sourced biomass is not only an excellent feedstock for renewable fuels production, but also for chemicals. Indeed, the increased use of natural gas (shale gas in particular) will lead to shortages in the key chemicals propylene, butadiene, and BTX, providing an additional economic incentive for chemicals production from biomass. Lignocellulosic bio-oils produced by catalytic pyrolysis are, after the necessary upgrading steps, are particularly attractive for both renewable fuels (addressing the energy-challenge) and chemicals (addressing projected chemicals scarcity). One of the most advantageous ways of bio-oils to fuels conversion is by co-feeding the bio-oil in a conventional fluid catalytic cracking process (FCC), but at present this approach suffers from reduced gasoline production and increased coking. Alternatively, the bio-oil can be catalytically upgraded to aromatics and olefins, a process that at present also suffers from catalyst deactivation and limited selectivity. We will study catalyst deactivation for these two processes in detail a combined experimental and spectroscopic approach to come to structure-activity relations and ultimately to guidelines for improved catalyst composition and performance. In a parallel study, a detailed FCC reactor model will be developed that predicts the performance based on first principles, which can be used to test different scenarios for the operation of these reactors.

Project leader: Prof. Bert Weckhuysen