Open micro-structured random packing in GLS reactors for FT: multi-scale reactor modelling

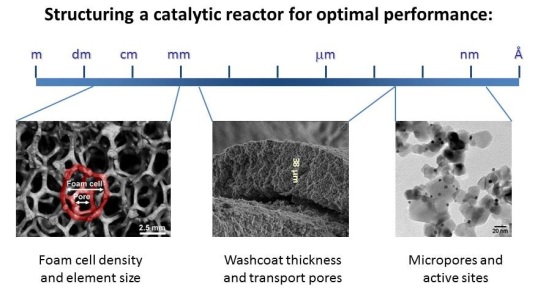

The Fischer-Tropsch process is widely applied to convert a variety of resources, such as gas, biomass and coal, to fuels. The reactions in this process are very fast, which makes that transport to the catalyst, which performs the reaction, is often limiting the reaction rate. As a result, the process is not optimally efficient, but even worse, the product composition will deviate. In this project, we will design a new catalytic reactor with a very accessible structured solid foam catalyst, optimizing the transport properties on all length scales, from the nanometer scale of the active site where the reaction occurs up to the meter scale of the reactor itself.

Project leader: Prof. Hans Kuipers