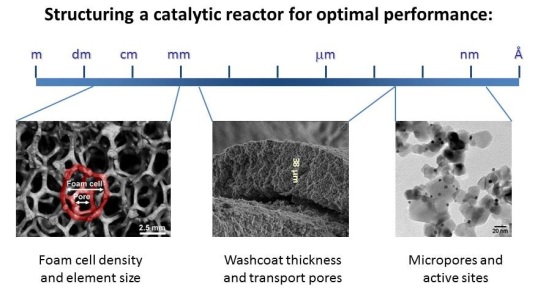

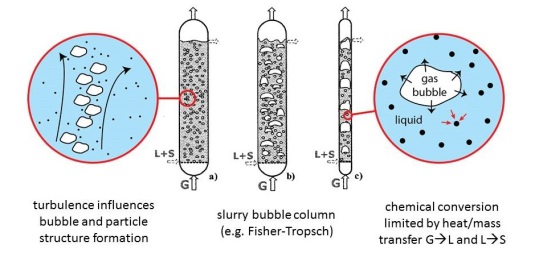

A variety of large-scale manufacturing and transport processes encounter dispersed multiphase flows, i.e., flows with dispersed bubbles or particles. These in particular include flows in chemical plants and flows in which catalytic chemical reactions occur, such as in the Fischer-Tropsch method. All these dispersed multiphase flows are not laminar, but turbulent.

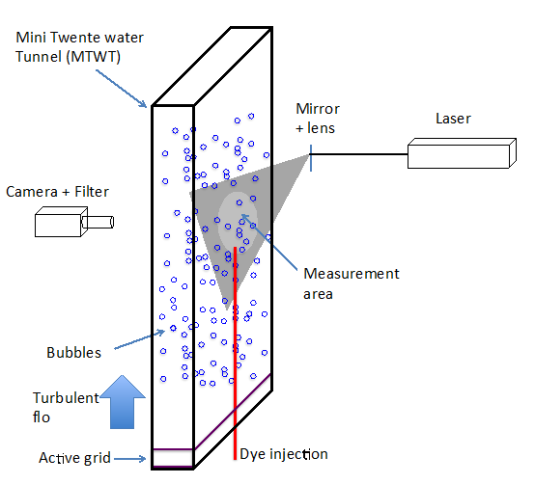

The questions we want to address in this project are: How do bubbles affect mixing of reactants (or in general a scalar field) in such bubbly turbulent flows? How do bubbles change the mixing efficiency? What are the optimal parameters for the mixing of reactants?

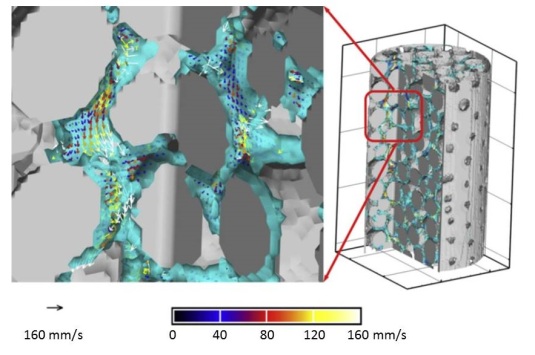

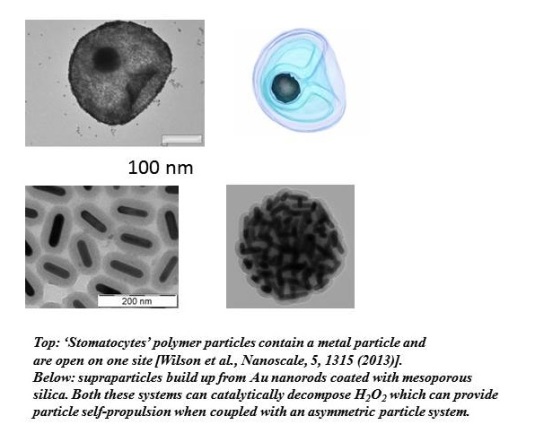

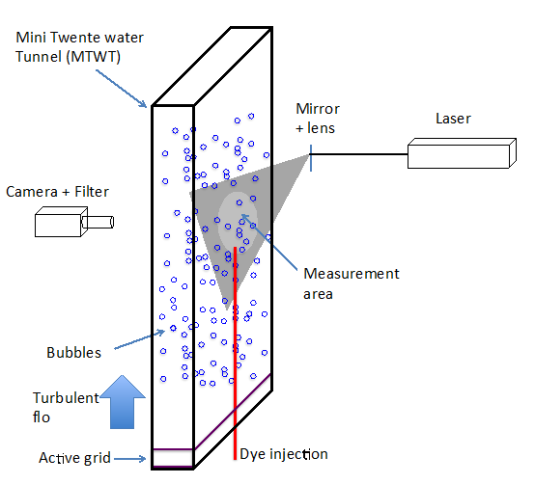

In the present project, we propose to study the mixing of passive scalar fields such as in reaction products out of a catalytic reaction (on floating microparticles) in a freely rising bubble swarm. In addition, we intend to investigate the effect of turbulence on the mixing, aiming to address the interplay between the bubbles, the catalytic particles, and turbulent fluctuations on the mixing in turbulent multiphase flows.

Project leader: Prof. Detlef Lohse